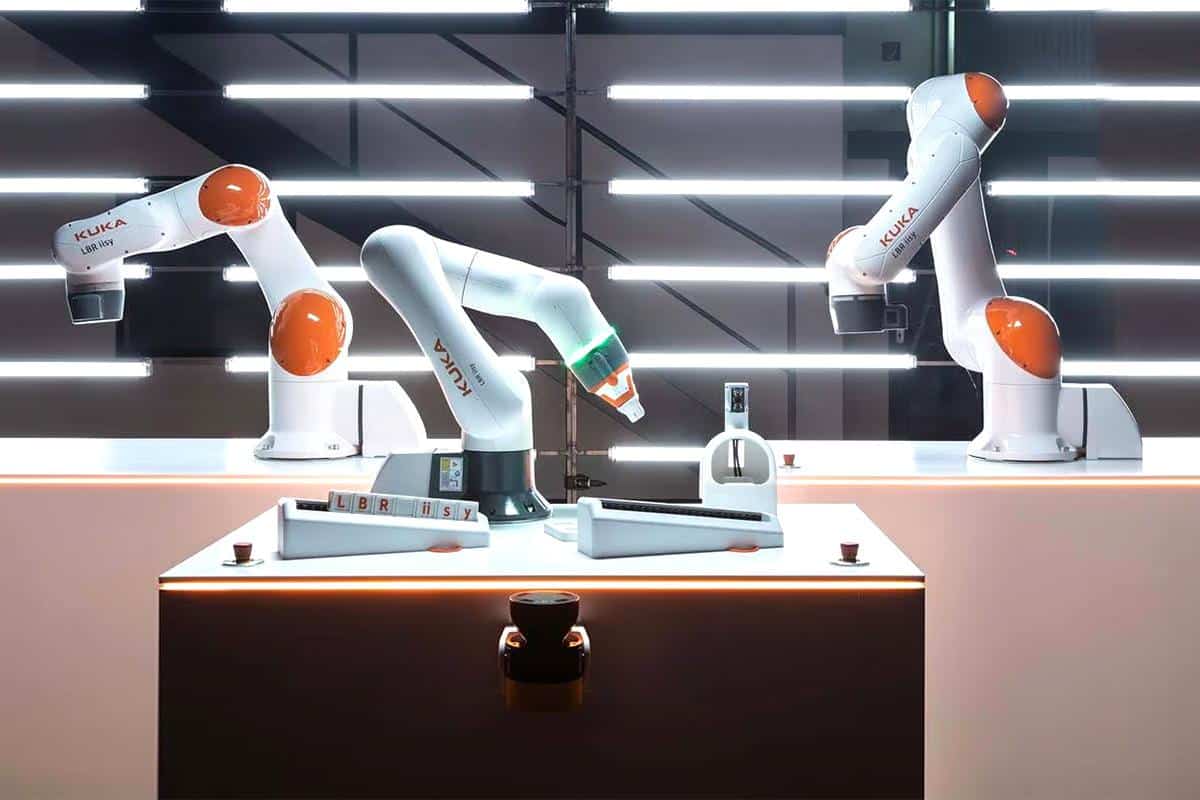

Highly versatile, intuitive to operate and reliable in contact with humans – the KUKA LBR iisy is an industrial collaborative robot for all production areas. The 'cobot' combines the know-how of industrial automation with the flexibility and simplicity of an intelligent tool, paired with the speed of a traditional industrial robot.

SCM HANDLING

KUKA LBR iisy COBOT

Set it up, switch it on, get started

Ready for use in just a few minutes – the LBR iisy industrial collaborative robot stands out due to its intuitive operating features, which ensure that it can be put to use quickly and productively without any prior knowledge.

The cobot uses the iiQKA.OS operating system, making it easy to install, configure and program. Tasks can be taught really easily by means of manual guidance. Thanks to the smart teach pendant smartPAD pro, any additional programming tasks are as easy as using a smartphone. An optional pre-installed and pre-configured gripper makes the cobot even easier to use.