SCM HANDLING

PALLETISING SYSTEMS

WHAT IS

AUTOMATED ROBOTIC PALLETISING?

BESPOKE SYSTEMS

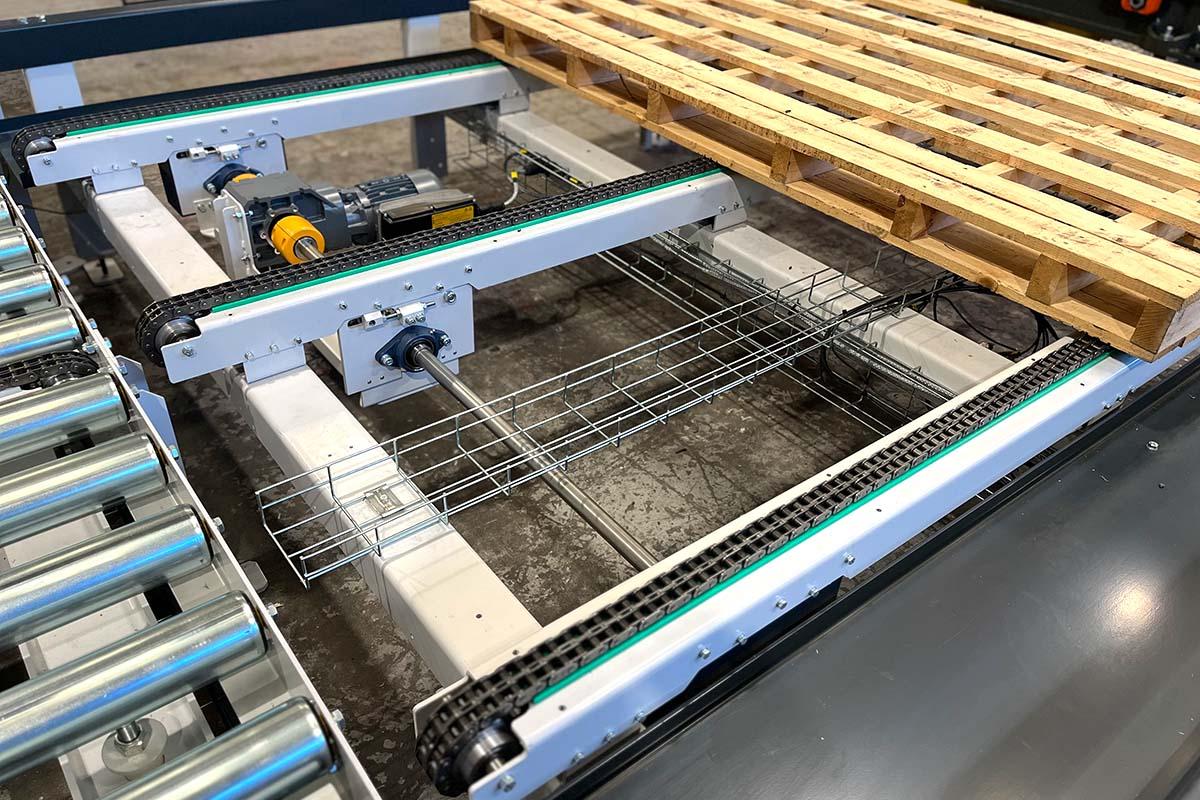

Our full turnkey approach to palletising includes case erectors, sealers, check weighers, strappers, pallet wrappers and labelling machines; providing a 'one stop shop' for end users

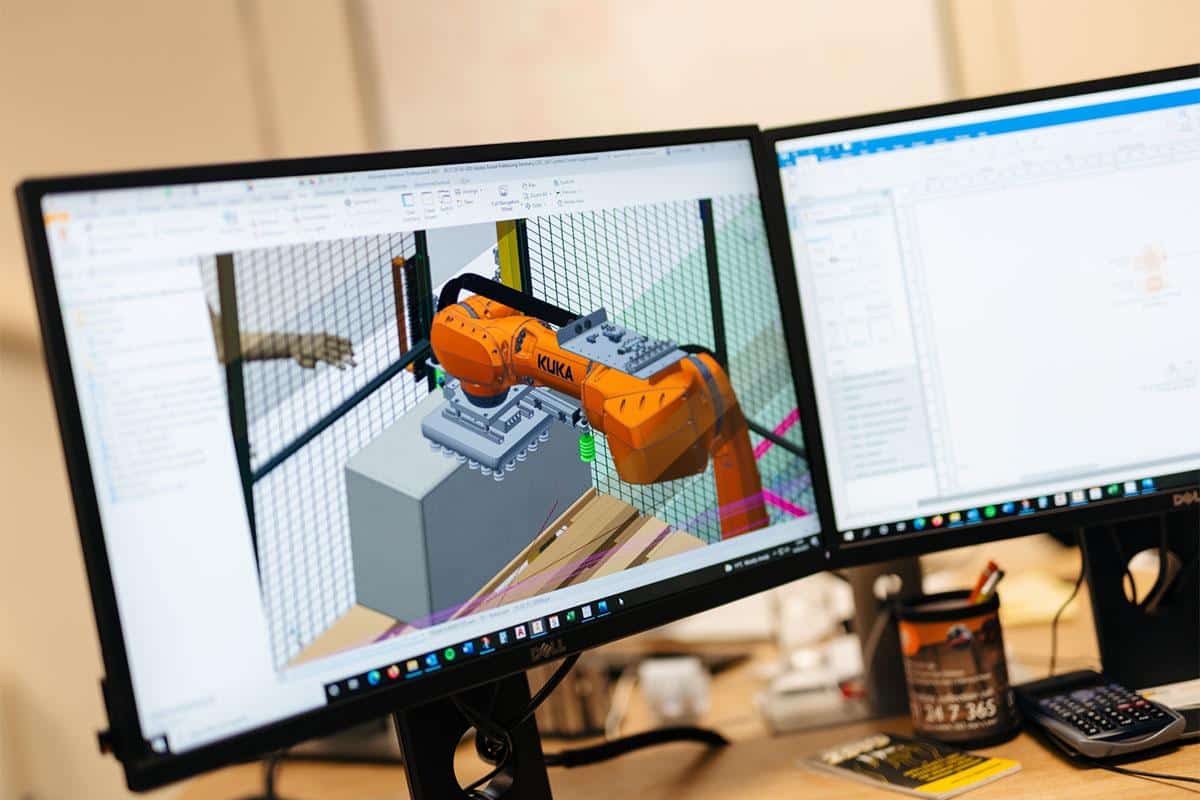

DIGITAL DESIGN

All of our automated robotic palletising systems are designed using Autodesk Inventor 2023

KUKA Sim Pro smart simulation software enables us to perform configurable collision testing, distance check & cycle time determination

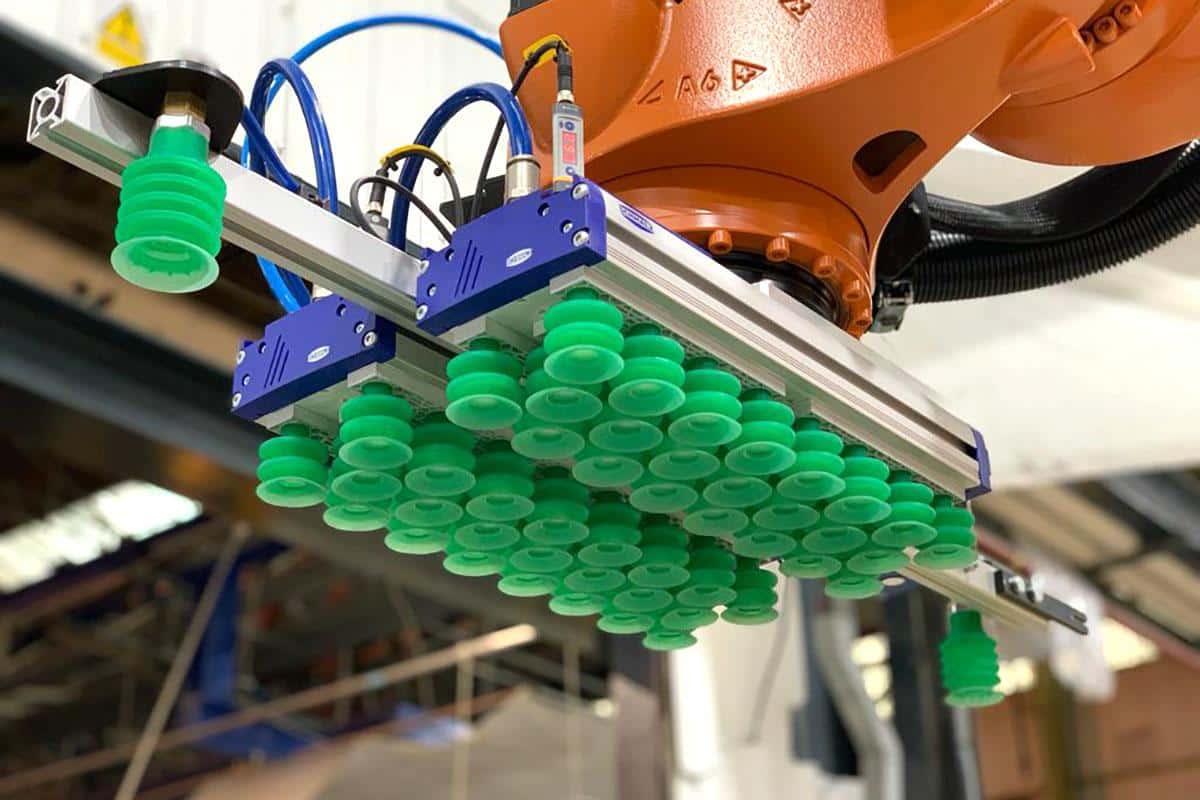

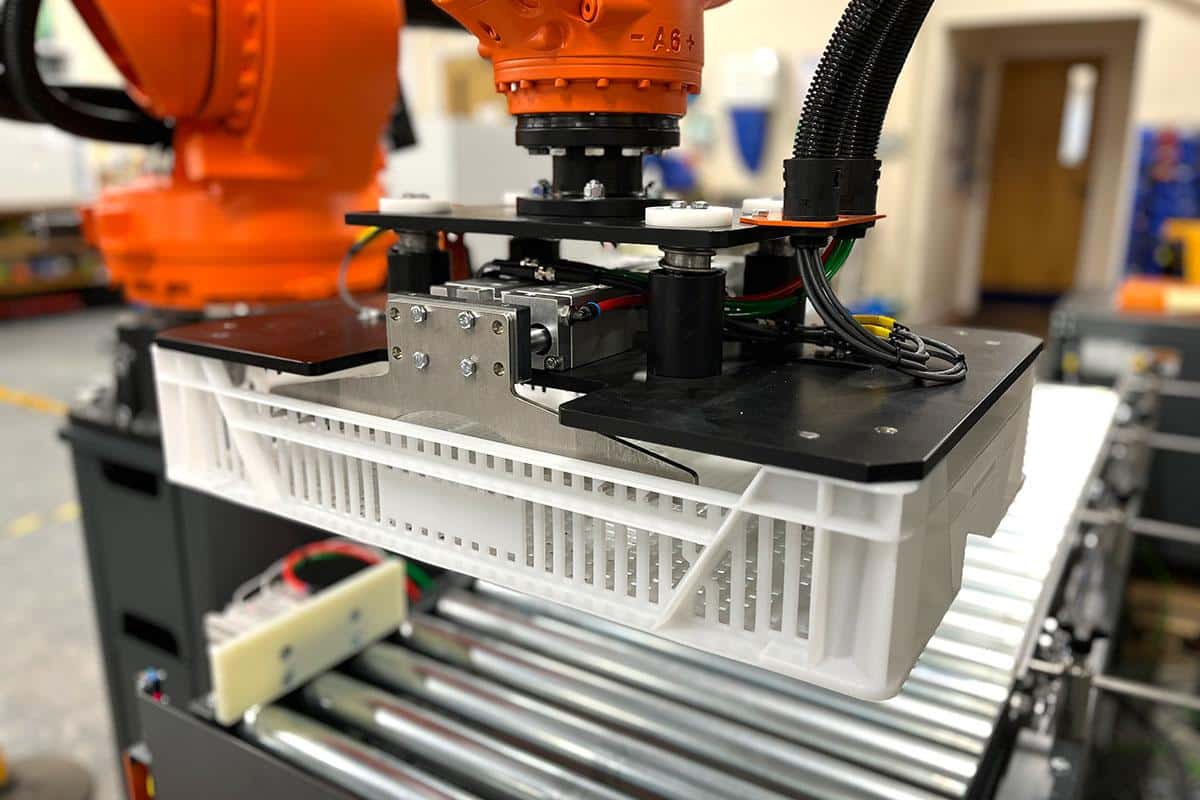

WORLD-CLASS COMPONENTS

We utilise KUKA’s innovative range of Quantec palletising robots combined with our industry leading pallet handling equipment & 24v conveyor

SETUP & INTEGRATION

Our engineers are proficient in programming Siemens and Allen Bradley PLCs as well as Siemens Technology motion control and Siemens S7 series processors

We also have extensive experience in integrating systems with a large variety of plant-wide control networks including ModBus, CANOpen and FTP

Our palletising systems can be accessed remotely allowing us to dial in an fault diagnose from our UK facility